What is an Infrared Thermographic Inspection?

It is the art and science of detecting thermal patterns on an object’s surface. All objects that are over 0 Kelvin do emit infrared energy. Using a specialized thermal imager, this energy is captured and converted into an image which depicts the thermal pattern of the object’s’ surface.

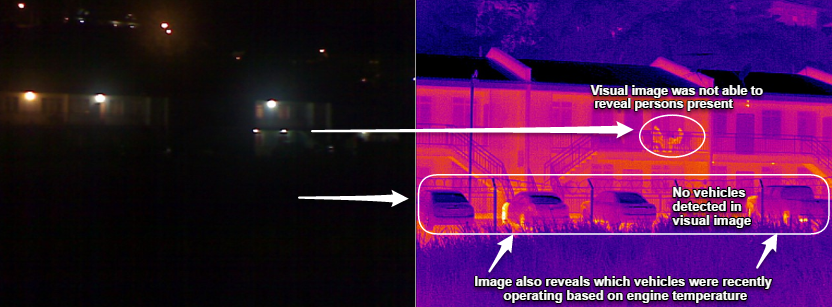

In the above images note that:

The visual image has very minimal information.

The infrared image shows an abundance of useful information for surveillance purposes. For example, location of persons on the compound, vehicles on the compound and by extent, which vehicle was recently in operation due to the thermal image patterns seen on the engine areas.

What can an Infrared Thermographic Inspection provide?

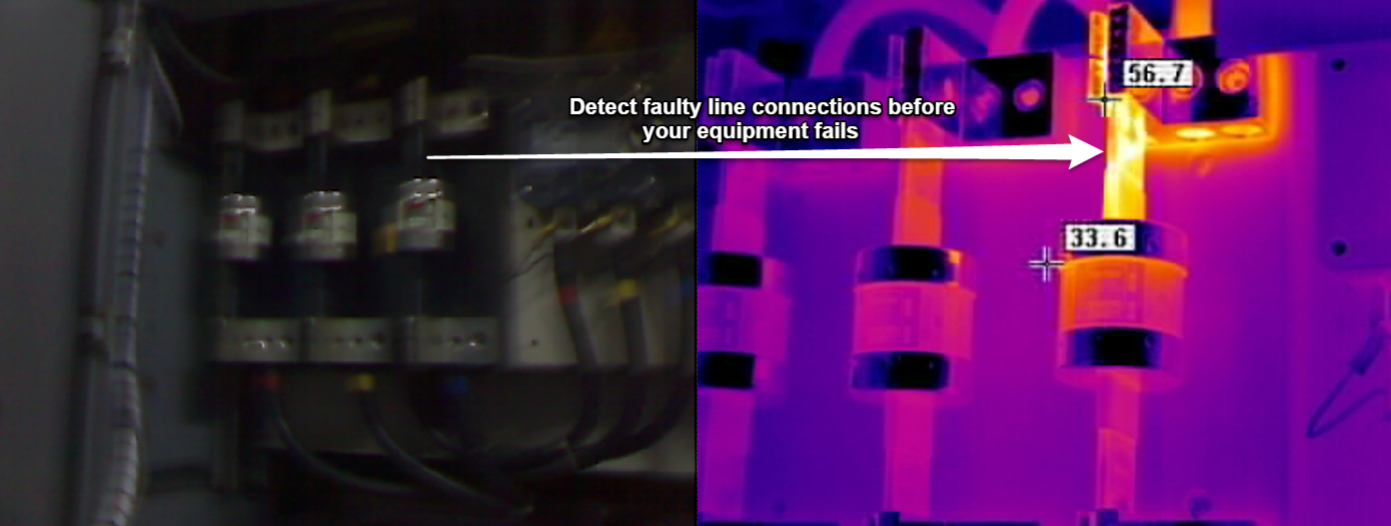

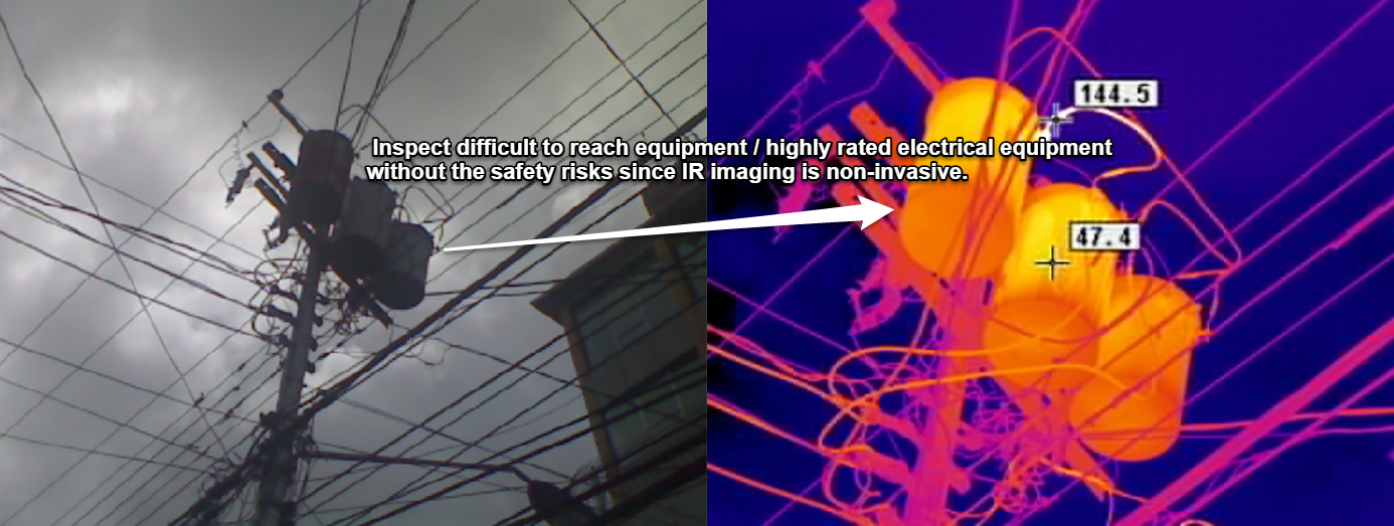

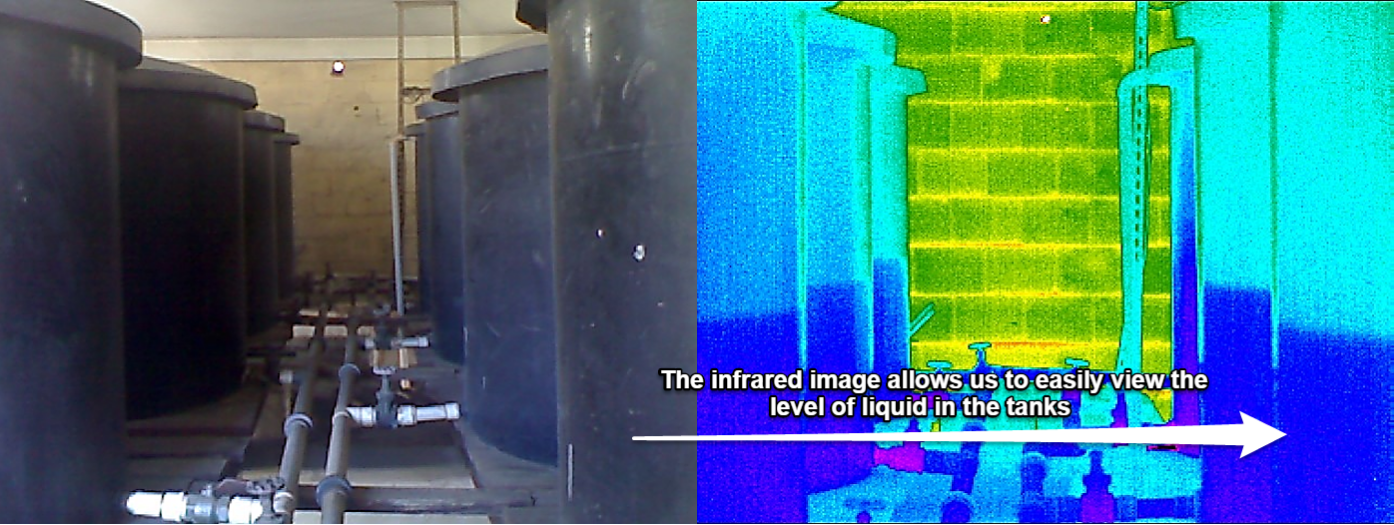

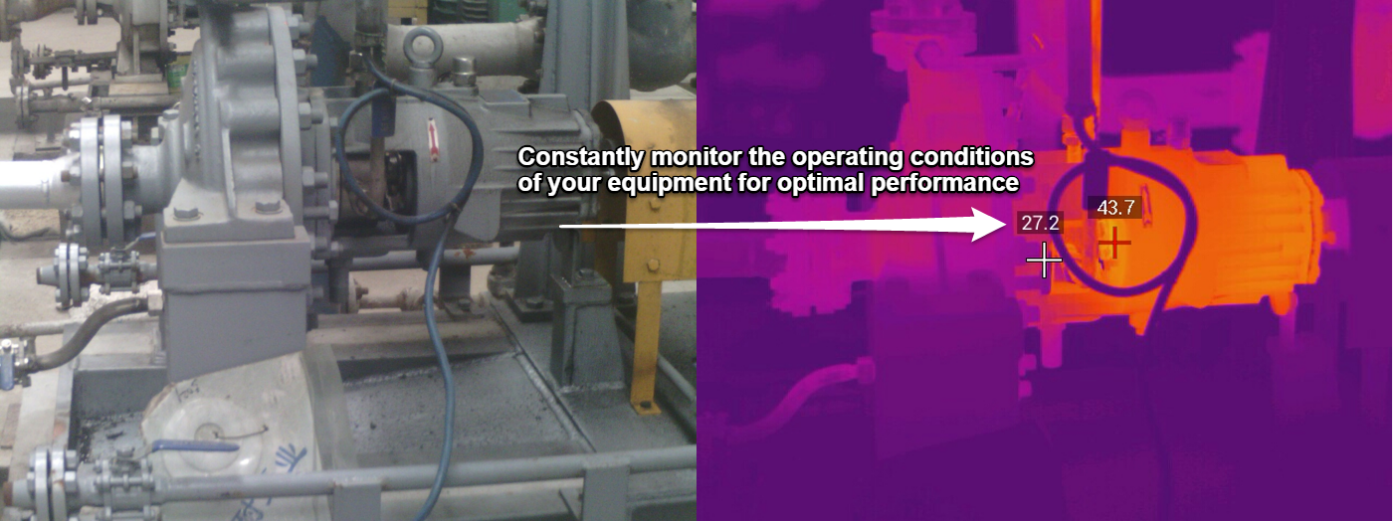

Information! – An Infrared Thermographic Inspection provides quality information on the real time condition of assets (Electrical, Mechanical, Facilities etc). But why is this information relevant? Managers, Maintenance Personnel, Investors & all stakeholders who have interest in their assets’ longevity and effectiveness can use this information to ensure that its performance is not compromise.

After an inspection is completed, a report is generated and submitted to the client for their review. All issues discovered are prioritised. The client can use this information to develop a strategic plan to address findings!